High-pressure hoses are robust conduits designed to withstand elevated pressures in demanding applications across various industries. These hoses are engineered using materials like synthetic rubber, thermoplastics, or PTFE, reinforced with sturdy braids or spirals of steel or synthetic fibers to handle high-pressure conditions effectively.

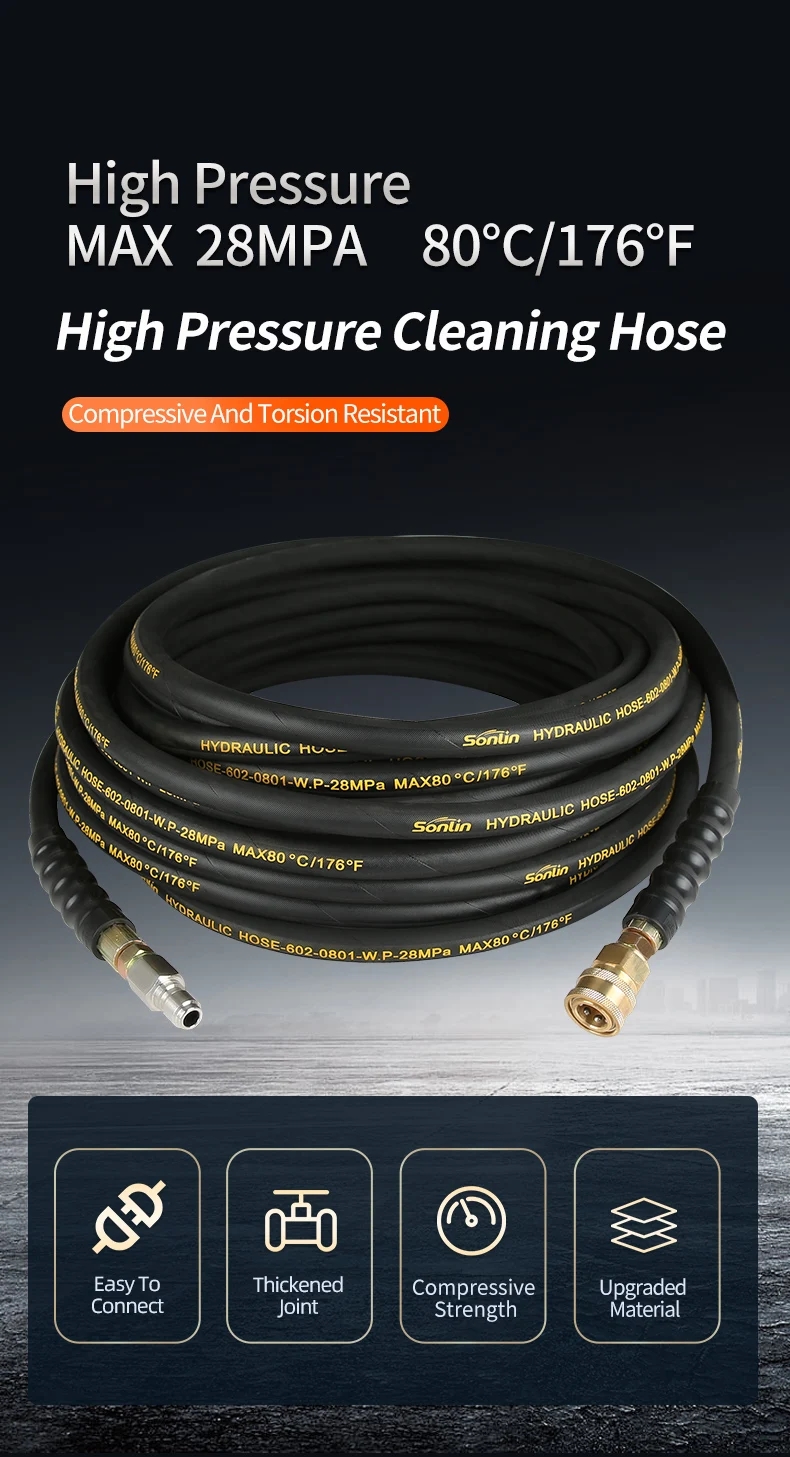

They are specifically crafted to endure extreme internal pressure without compromising structural integrity. High-pressure hoses come in different types and designs suitable for specific applications, such as hydraulic hoses used in heavy machinery, water blasting hoses, paint spray hoses, or pneumatic hoses for compressed air systems.

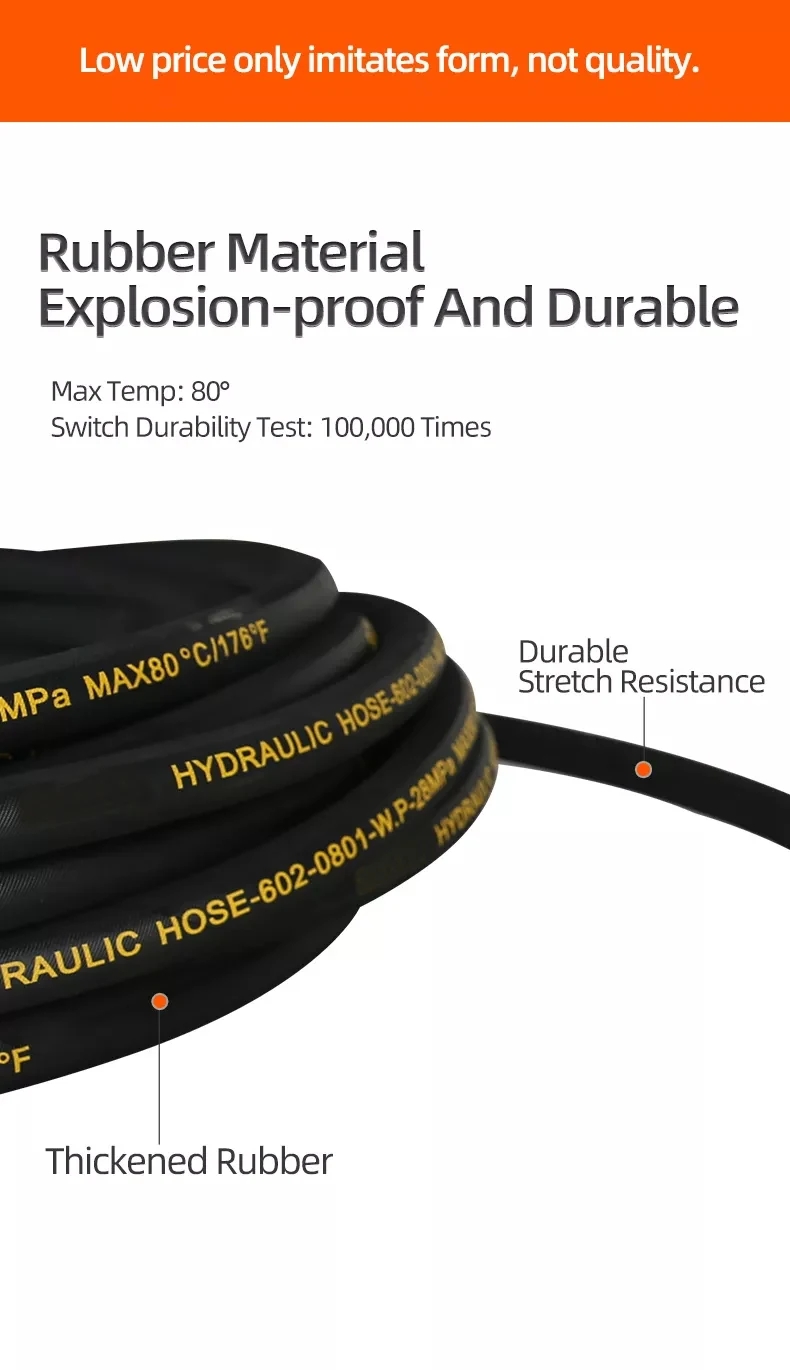

The construction of these hoses ensures resistance to abrasion, corrosion, and wear, providing durability in harsh environments. Their flexibility allows them to navigate tight spaces and complex systems while maintaining consistent flow under pressure.

High-pressure hoses find widespread applications in industries like construction, manufacturing, oil and gas, agriculture, and more. They are essential components in hydraulic systems, power steering, pressure washers, and various machinery requiring controlled power transmission.

Proper maintenance and adherence to pressure ratings are crucial for safe operation. Regular inspections and replacement when worn or damaged are essential to prevent potential hazards associated with high-pressure applications. Overall, high-pressure hoses play a critical role in facilitating the reliable and controlled transmission of fluids or gases in industrial settings where pressure is a primary concern.