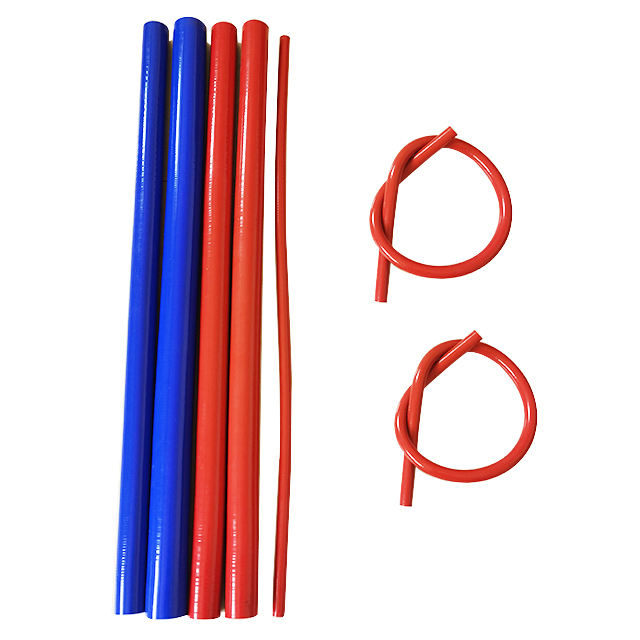

The evolution of silicone hoses

The evolution of silicone hoses has been a result of continuous advancements in materials, manufacturing techniques, and the expanding needs across various industries. Here’s an overview of the key stages in the evolution of silicone hoses: Introduction of Silicone Rubber: Silicone rubber, the primary material used in silicone hoses, was first developed in the mid-20th …