Rubber hoses are flexible tubes crafted from natural or synthetic rubber compounds designed to convey fluids, gases, or solids in a multitude of applications across industries. These hoses are constructed using various rubber materials like natural rubber, nitrile, neoprene, EPDM, or silicone, each offering distinct properties suited for different purposes.

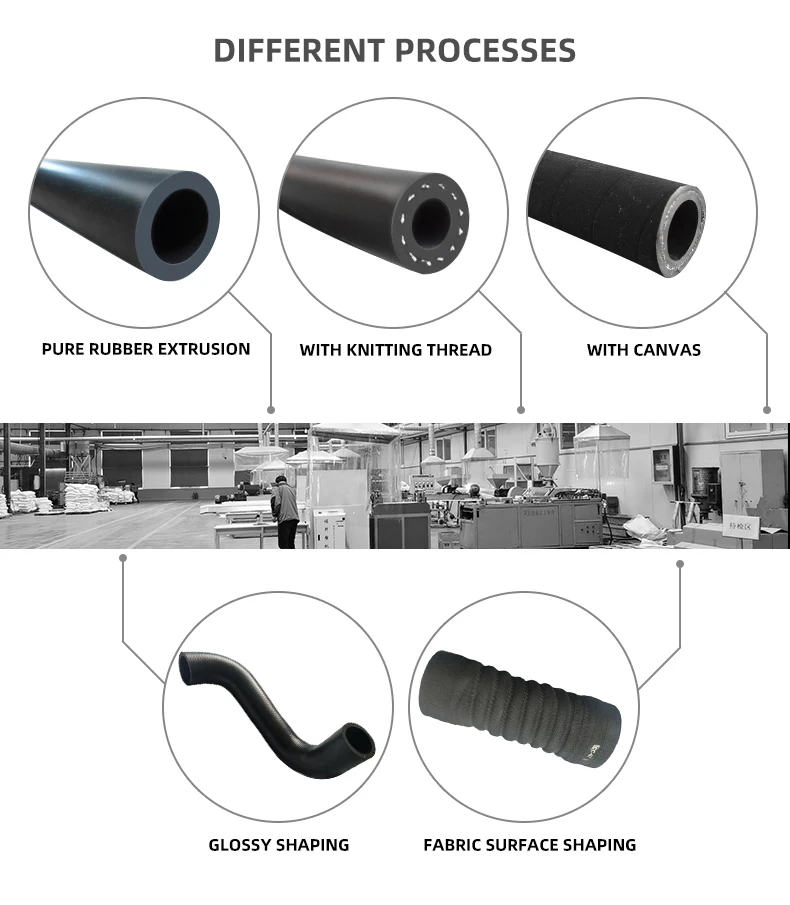

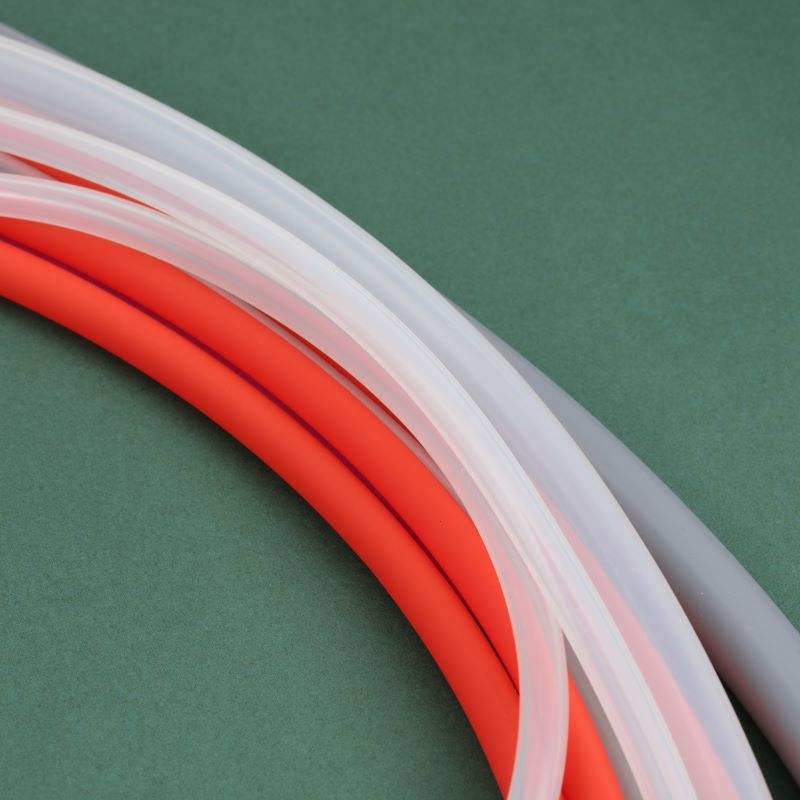

They excel in flexibility, allowing easy bending and maneuverability, making them adaptable to diverse installation requirements. Rubber hoses are available in numerous configurations, including straight, coiled, corrugated, or reinforced with textile or wire braids for added strength and resilience.

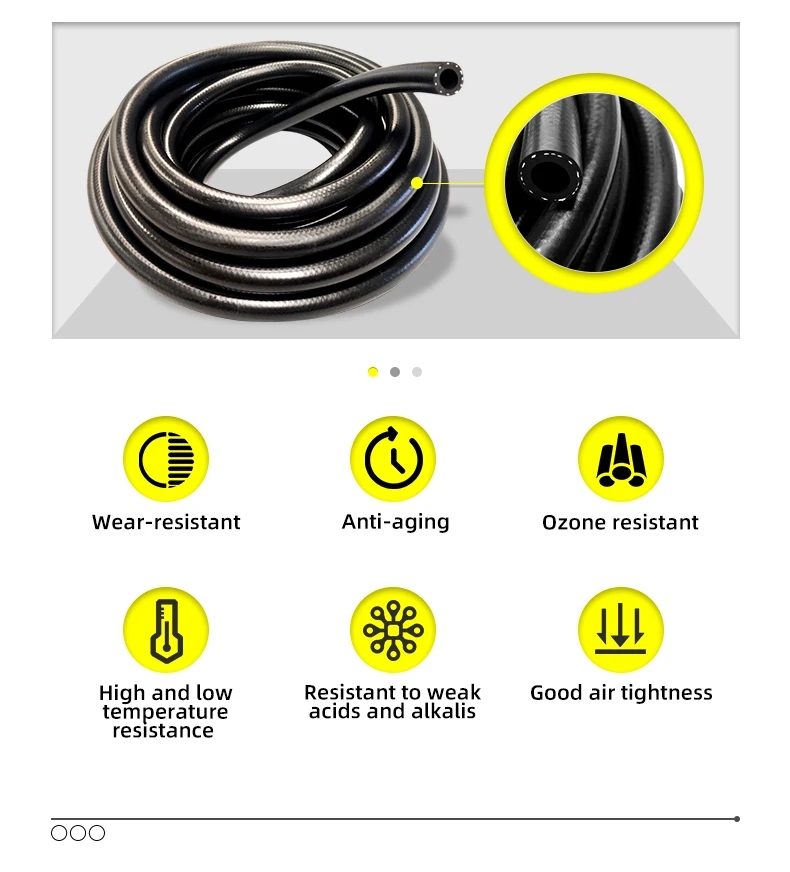

The versatility of rubber hoses extends to their resistance to a wide range of substances like water, oil, chemicals, abrasion, and weathering. This resistance makes them suitable for applications in automotive systems (such as fuel lines, coolant systems), construction (for concrete pumping or air/water delivery), agriculture, manufacturing processes, and more.

Additionally, rubber hoses exhibit excellent temperature resistance, enabling them to operate effectively in various temperature ranges, from extreme cold to high heat conditions. Their insulation properties make them valuable in electrical insulation applications.

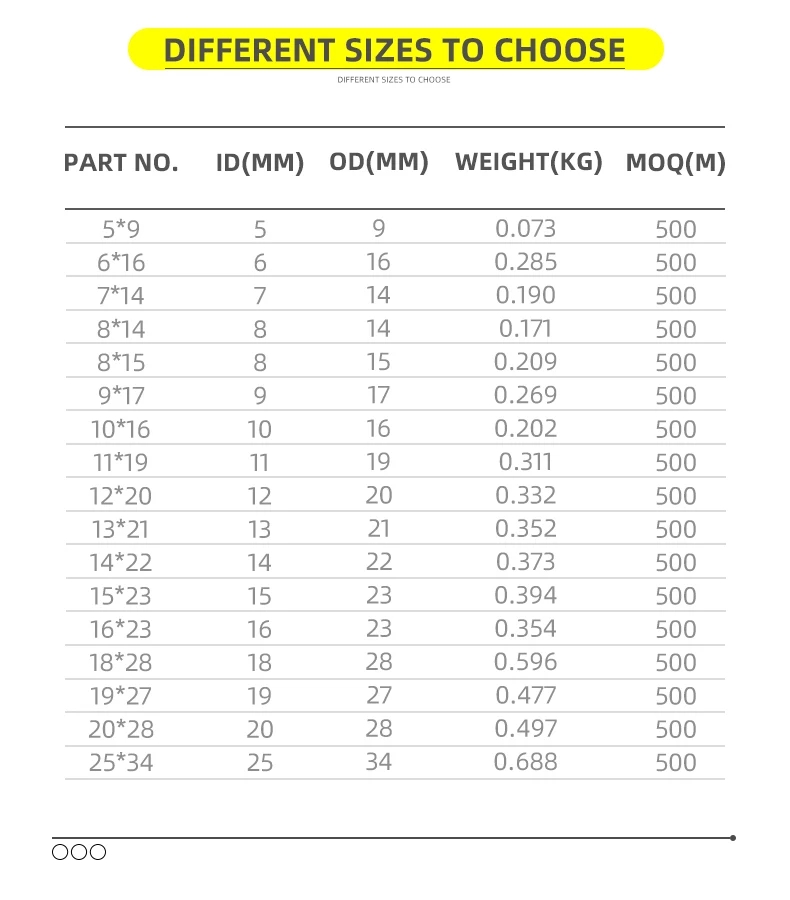

The availability of rubber hoses in different sizes, shapes, and configurations, coupled with their durability and adaptability, contributes to their widespread use across industries, meeting diverse fluid transfer and containment needs reliably.