Polytetrafluoroethylene (PTFE) hoses are exceptional conduits known for their unparalleled chemical resistance, high-temperature tolerance, and exceptional dielectric properties. Composed of PTFE, a synthetic fluoropolymer, these hoses boast outstanding resistance to corrosive fluids, acids, solvents, and aggressive chemicals across a wide pH range.

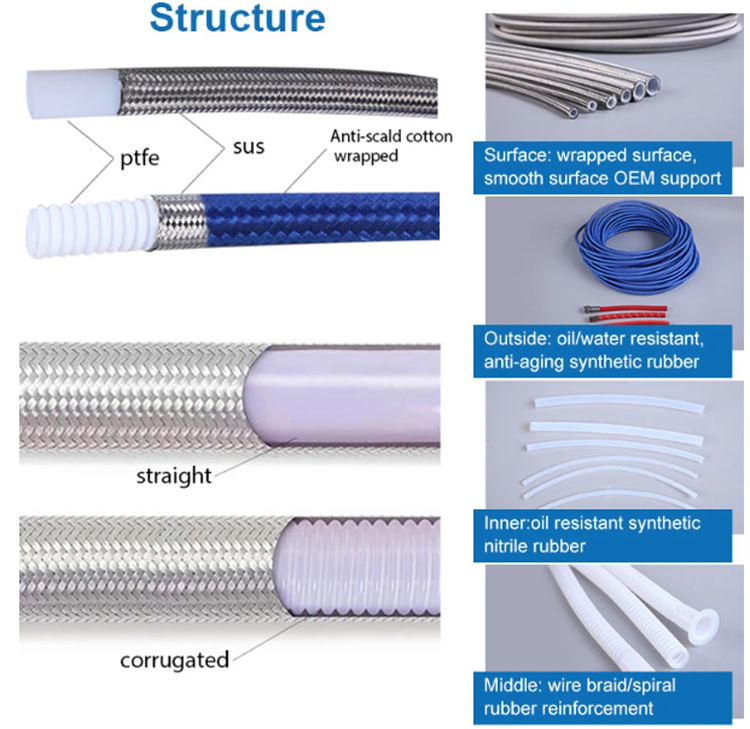

The structure of PTFE hoses comprises a smooth, non-stick surface, minimizing friction and allowing the efficient flow of substances without contamination. This property makes them ideal for critical applications in pharmaceutical, chemical processing, food and beverage, and aerospace industries.

PTFE hoses exhibit exceptional thermal stability, maintaining their structural integrity in extreme temperature conditions, ranging from cryogenic levels to high heat environments. They also possess excellent dielectric properties, making them valuable in electrical applications.

Their flexibility and resistance to fatigue ensure longevity and reliability in demanding applications, while their non-reactive nature makes them suitable for transferring sensitive or reactive materials without alteration or contamination.

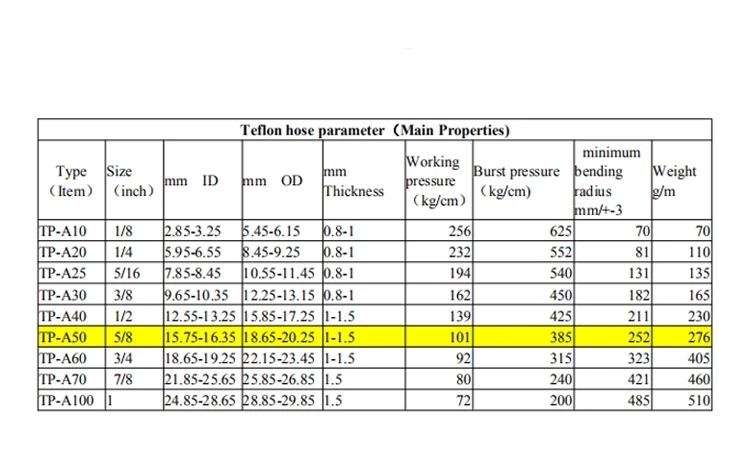

PTFE hoses come in various configurations, including convoluted or smooth-bore designs, offering options for different flow requirements and installation needs. These hoses, when reinforced with stainless steel braids or other materials, enhance their pressure resistance and flexibility, expanding their utility across various industrial sectors requiring high-performance fluid transfer solutions.